Improper refrigeration of food during transportation and storage costs billions of US dollars per year. In fact, roughly one-third of the food produced in the world for human consumption every year — approximately 1.3 billion tons — gets lost or wasted. When food isn’t stored properly, it leads to excessive amounts of food waste and lost income and other resources. Additionally, regulatory standards are getting tougher and tougher. There is a reinforcement of regulations for every stage of logistics and distribution for food, including the following in various countries: HACCP, Hygiene Package, EN 12830FDA, and the Food Safety Modernization Act (FSMA) in the US.

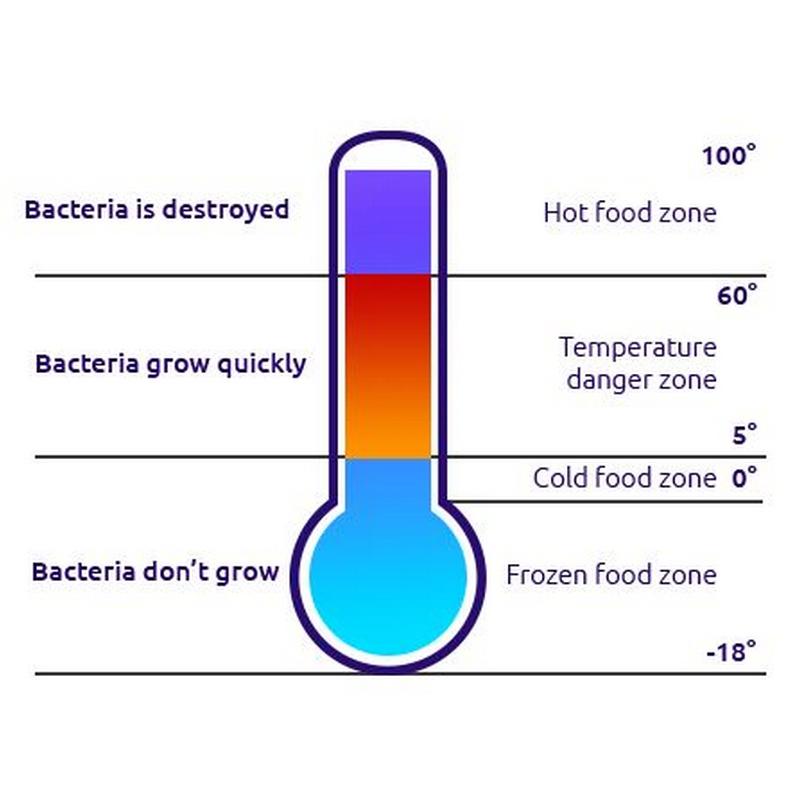

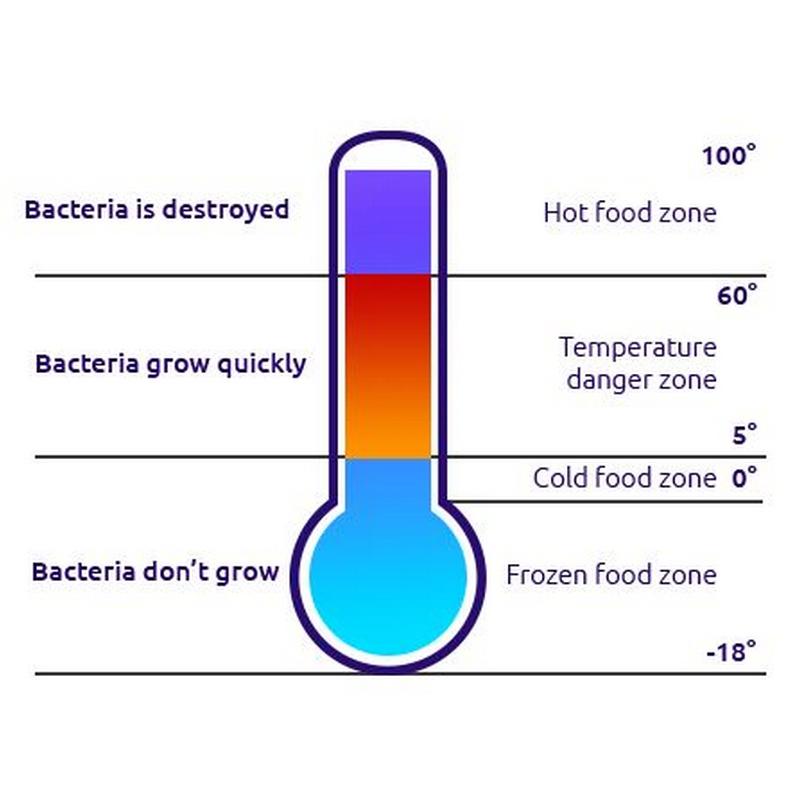

Besides lost income and food, improper food temperatures during transport, storage, and serving is a risk to public health. Bacteria growth in undercooked food can lead to severe illness. In fact, almost half a million people are killed annually by food poisoning around the world.

What’s more, even if 25 percent more food was stored properly and not lost, it could feed almost a billion people around the world each year.

Better tracking of temperature could help ward off food waste, especially because manual temperature monitoring is susceptible to human error, including a failure to record the temperature regularly, inaccurate measuring, or not enough monitoring.

Improper refrigeration of food during transportation and storage costs billions of US dollars per year. In fact, roughly one-third of the food produced in the world for human consumption every year — approximately 1.3 billion tons — gets lost or wasted. When food isn’t stored properly, it leads to excessive amounts of food waste and lost income and other resources. Additionally, regulatory standards are getting tougher and tougher. There is a reinforcement of regulations for every stage of logistics and distribution for food, including the following in various countries: HACCP, Hygiene Package, EN 12830FDA, and the Food Safety Modernization Act (FSMA) in the US.

Besides lost income and food, improper food temperatures during transport, storage, and serving is a risk to public health. Bacteria growth in undercooked food can lead to severe illness. In fact, almost half a million people are killed annually by food poisoning around the world.

What’s more, even if 25 percent more food was stored properly and not lost, it could feed almost a billion people around the world each year.

Better tracking of temperature could help ward off food waste, especially because manual temperature monitoring is susceptible to human error, including a failure to record the temperature regularly, inaccurate measuring, or not enough monitoring.

Proper monitoring of food temperature has four components: data collection, communication, data administration, and results.

Let’s take an example of how IoT food temperature monitoring solution is used. If a restaurant is using Sigfox-powered sensor technology to monitor their food cold storage temperatures, they can set an alert to be notified if the temperature raises or drops below the safe range.

One day, a storage refrigerator goes 7 degrees over the safe range. The sensor sends an SMS text and email alert to the restaurant owner. He checks the refrigerator and sees that it is no longer powered on and won’t work anymore. The restaurant owner quickly has his staff move the food to another refrigerator. He can now get his refrigerator repaired, but ends up saving money because no food was lost.

Even if the power were lost to the restaurant, as they run on batteries and send data directly to the Cloud via the Sigfox network, the s data would be safe in a power outage and the cold chain monitoring system still active.

Proper monitoring of food temperature has four components: data collection, communication, data administration, and results.

Let’s take an example of how IoT food temperature monitoring solution is used. If a restaurant is using Sigfox-powered sensor technology to monitor their food cold storage temperatures, they can set an alert to be notified if the temperature raises or drops below the safe range.

One day, a storage refrigerator goes 7 degrees over the safe range. The sensor sends an SMS text and email alert to the restaurant owner. He checks the refrigerator and sees that it is no longer powered on and won’t work anymore. The restaurant owner quickly has his staff move the food to another refrigerator. He can now get his refrigerator repaired, but ends up saving money because no food was lost.

Even if the power were lost to the restaurant, as they run on batteries and send data directly to the Cloud via the Sigfox network, the s data would be safe in a power outage and the cold chain monitoring system still active.

Not only will these benefits help you achieve higher productivity, you’ll also have more control over your food safety. These benefits include:

-Easy installation

-Simplicity of use

-Automated Temperature Monitoring = Peace-of-Mind

-Reduced Waste

-Energy Saving

-Better food storage performance and quality

-Affordable monitoring solution

-Easier compliance monitoring

-Better safety for customers and clients

Not only will these benefits help you achieve higher productivity, you’ll also have more control over your food safety. These benefits include:

-Easy installation

-Simplicity of use

-Automated Temperature Monitoring = Peace-of-Mind

-Reduced Waste

-Energy Saving

-Better food storage performance and quality

-Affordable monitoring solution

-Easier compliance monitoring

-Better safety for customers and clients